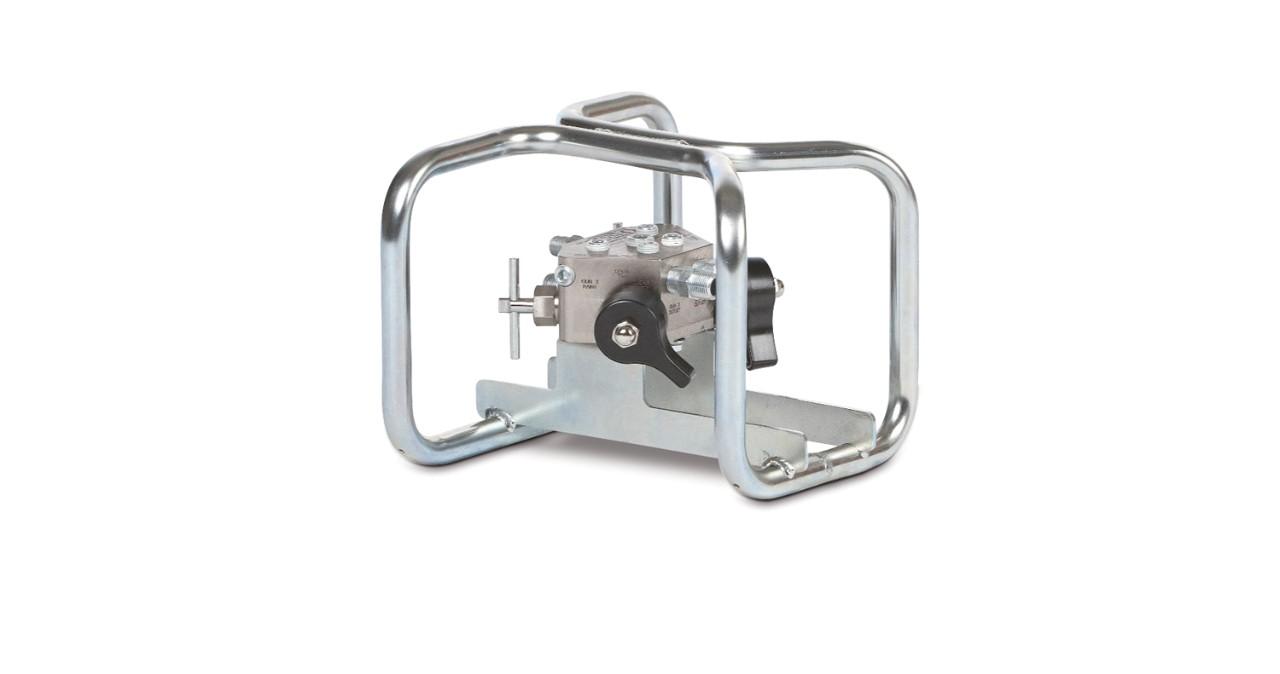

XP Plural-Component Sprayers

Contact SalesA smart alternative to hand mixing.

The Graco XP Plural-Component Sprayers are designed to pump, mix and atomize high-viscosity, high-solids coatings with superior results. When you upgrade from hand mixing, you’ll find that the XP provides excellent return on investment, by reducing material waste and by using less clean-up solvent.

Features & Benefits:

- Reduce waste and material costs

With the Graco XP, you reduce waste and save money because you only mix as much material as you need. No more throwing away unused material at the end of the day. No more residue left over in smaller pails or cans. You can buy material in bulk as well. - Less clean-up saves time and money

Only the parts that come in contact with mixed material must be cleaned during the job. Instead of flushing out an entire pump system that contains mixed material, you only need to flush the static mix tube and hose to the gun. Reduced cleaning time means you save labor costs and increase uptime. - Provides consistent material quality

No more guesswork or human error in measuring means you can improve throughput, cut back on material waste, and reduce rework. Materials are proportioned by precision positive displacement pumps and mixed accurately and on-ratio at the mix manifold. - Easy to operate – minimal training required

- Reduced maintenance costs

Whether you’re spraying a highsolids polyurethane or a marine epoxy, Graco helps you get the job done with a complete line-up of XP Plural-Component Sprayers.

Materials:

- Environmentally-friendly high solids coatings, with little or no solvent

- Hybrid polyurethanes

- Epoxies

- Very high solids coatings – up to 100% solids content

- Materials requiring heat (requires optional heaters)

- Fast-curing materials

Applications:

- Towers for wind turbines

- Fleet maintenance and shipbuilding

- Marine applications

- Railcar manufacturing and repair

- Structural steel

- Pipe and tank coating

- Bridges

- Water towers

- Wastewater treatment

- Manhole and sewer reconditioning

- Secondary containment

RELATED LINKS